Degradation by injection of oxidizing agents

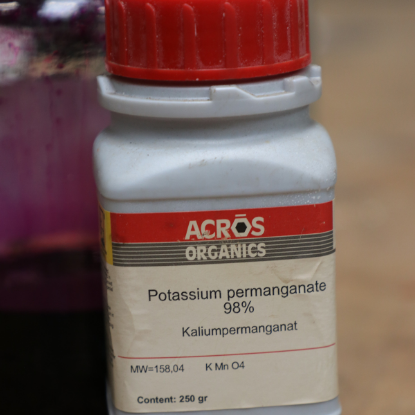

Groundwater Technology implements In Situ Chemical Oxidation (ISCO) by injecting a strong oxidant diluted in water. We use several oxidants that, when in contact, oxidize contaminants to harmless compounds. Multiple injections are often required to achieve full removal, partially because of the soil’s consumption of oxidizing agents. (matrix consumption).

Tailor-made injection

Matrix consumption and the nature & concentration of contaminants are key factors for us to determine the quantity and type of oxidizing agent:

Incomplete chemical oxidation could lead to partially oxidised degradation products. These compounds are often better available and more biodegradable than the original contaminants.

Persulphate Oxidation

When we implement persulphate based ISCO, we inject a diluted persulphate solution. Persulphate is a strong oxidizer which is more stable and remains active for a longer period than Modified Fenton’s reagens. In some cases we inject iron sulphate to activate the persulphate. Activation causes a quicker reaction and therefore a faster contaminant degradation. We also implement persulphate degradation as polishing step after a thermal in situ remediation. In this case, residual heat activates the persulphate.